I’m still having fun building parts for the Milan SL. My last piece was the head out lid and shade cap. After building these pieces, I realized that I should be able to stow the cap inside the Milan. The single piece cap assembled with its pillars doesn’t fit in the available space in the Milan. Stealing some ideas from Wim Schermer’s splittable Quest hood, I came up with a quick way to remove the pillars and split the cap into 2 pieces without tools.

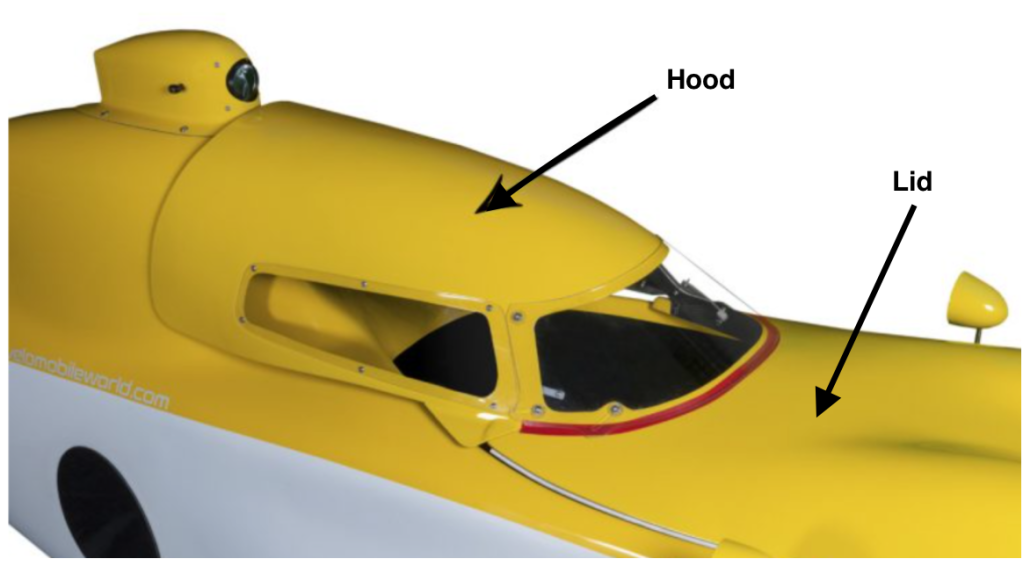

Here is the unpainted hood – split down the middle. At this stage, it still had the pillars mounted with screws.

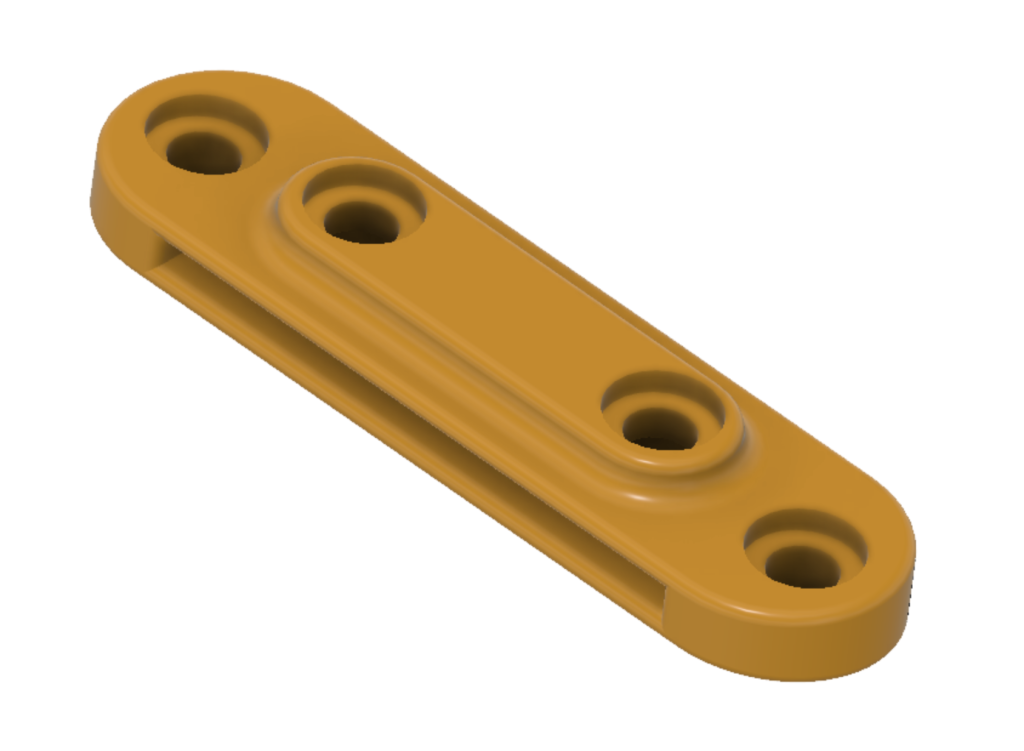

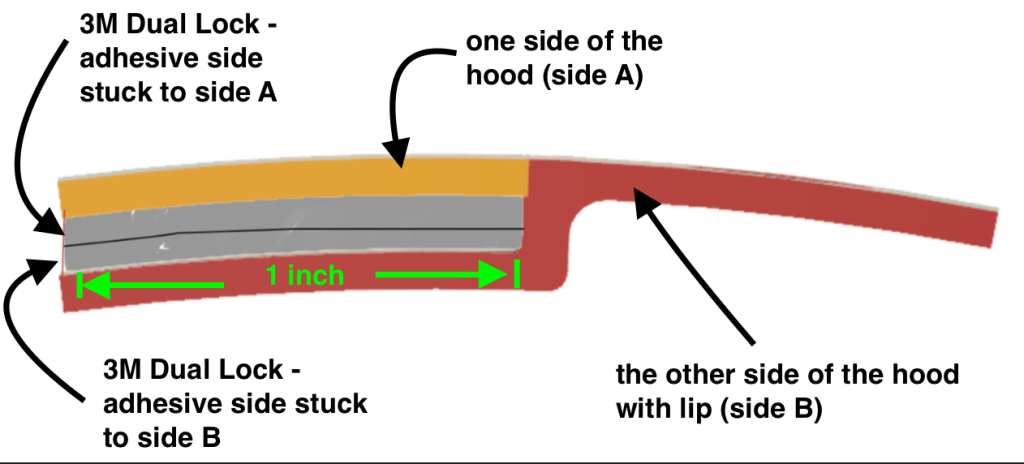

One of the problems I had to solve was to come up with a quick way to join the halves without using tools. I settled on using 3M Dual Lock. The idea was to fabricate a flange or lip on the underside of one half of the cap, for the full length of the split. The lip would have enough depth to allow 2 thicknesses of Dual Lock. Here’s a cross section to show what I mean.

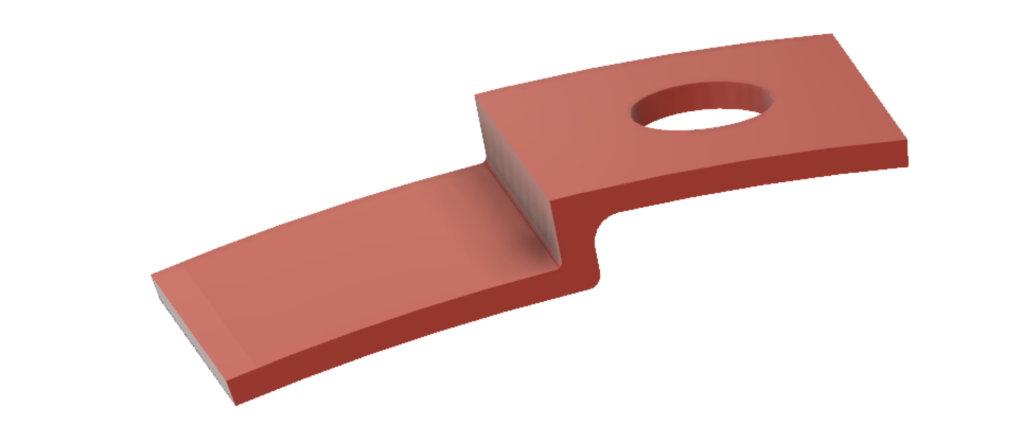

Laying up the flange didn’t sound like a lot of fun so I came up with an easier but less optimal way to accomplish the same thing by 3D printing something similar. Rather that printing a flange for the whole length of the split and trying to get the curvature right. I decided to print some 1″ long sections of flange, using carbon fiber/PETG filament, and epoxy them on one half of the cap along the split. Here’s the design of the piece. Also shown is the underside of the cap.

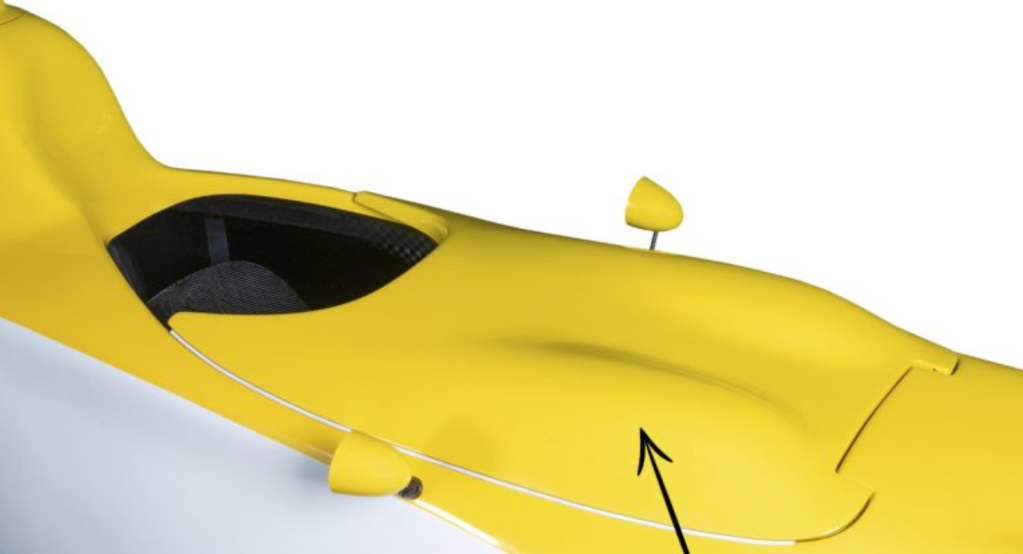

The next item to address was getting rid of the screws holding the pillars to the cap. I ended up using a slightly re-designed flange piece to attach the pillars using Dual Lock. Lastly, I wanted to get rid or the 2 allen screws on the clamps holding the lower pillars to the lid. I redesigned the clamp to use only a single M6 thumb screw. Here are some photos…

There’s a problem with the approach I’ve taken though. The split is not entirely sealed against the elements since there lip doesn’t run the whole length of the cap. If, over time, I find that this splittable cap is worth keeping, I’ll replace the one inch flange pieces with a full length carbon fiber flange.