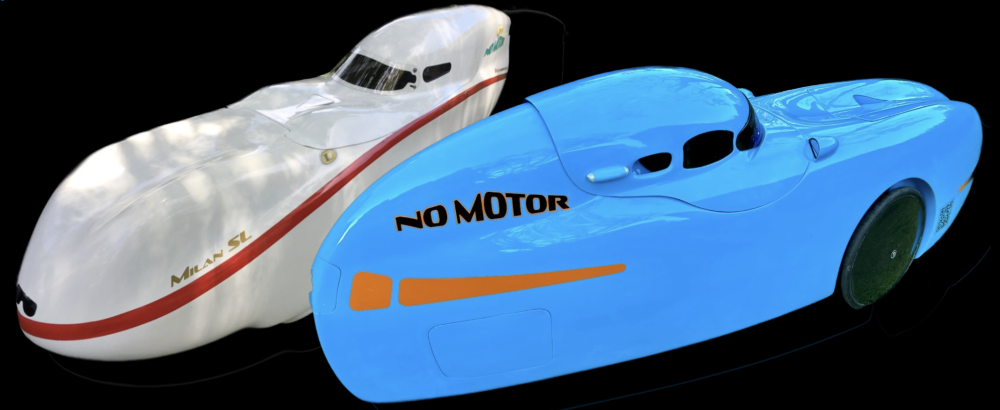

In the past, attaching Lexan side windows to my various hoods has always been sort of an afterthought. I’d cut out the opening in the hood, cut out an oversized piece of Lexan, then hot glue that piece to the hood from the inside. it worked OK but looked pretty crude. I’ve since come up with a little nicer approach.

The idea is to design and 3D print a flexible moulding similar to window mouldings used on car windows. The moulding is shaped to hold the Lexan while providing a lip that is glued to the body. The combination of Lexan window and moulding sits (almost) flush with the body. Here is what I came up with…

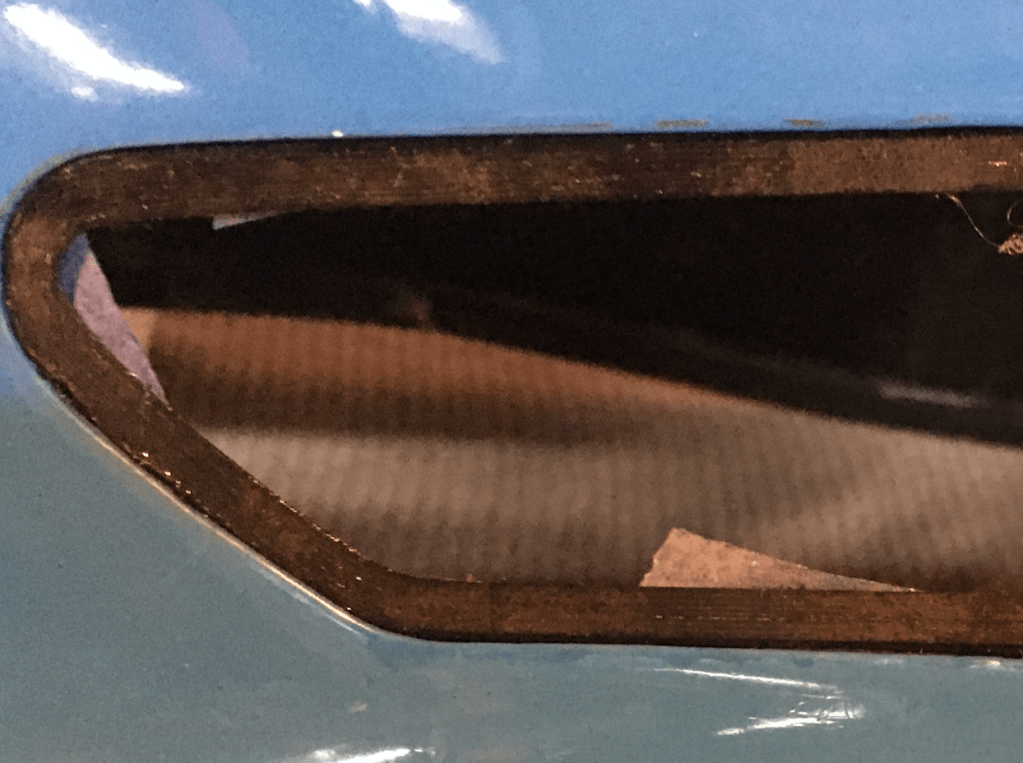

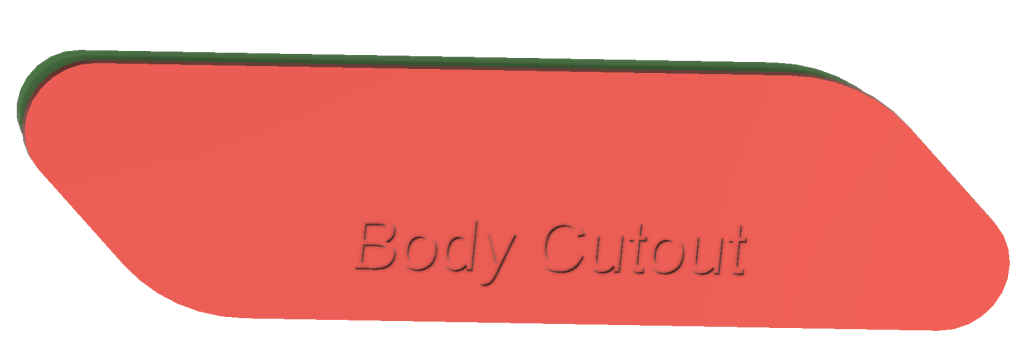

Using Fusion 360, I designed a template for the body cutout and a smaller template for the Lexan cutout. I printed a 3mm thick copy of each template. This particular shape is symmetrical so it can be used for either left or right side windows.

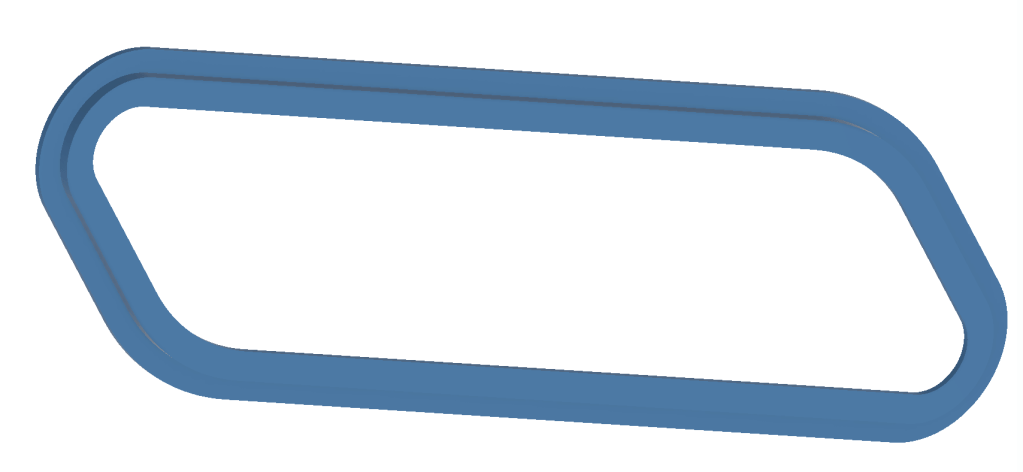

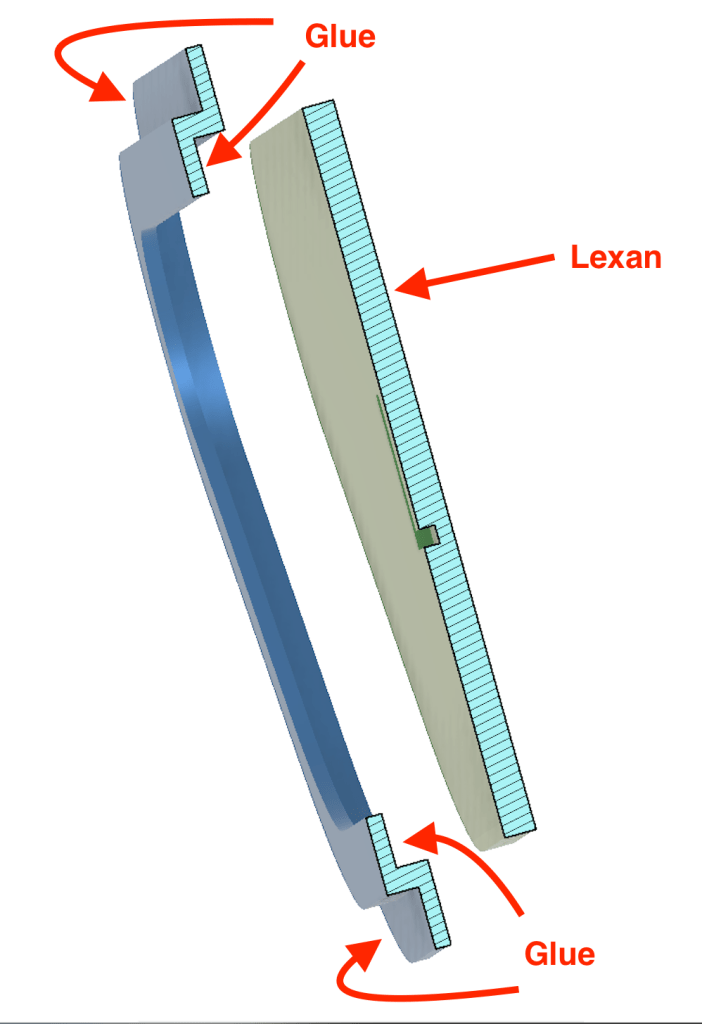

Next I designed the moulding, leaving an inset for the window and a lip that can be glued from the inside of the body. I 3D printed 2 copies of the moulding, one for each window, using the flexible filament called TPU.

Here is a cross section of the moulding.

Putting it together

After doing the design work in Fusion 360, the process to add lexan openings to body panels is pretty straight forward.

- Use the smaller Lexan cutout template to cut out the window. I use .030 in Lexan that can be cut with scissors.

- Use the larger Body cutout template to cut the opening in the body using a Dremel tool.

- 3D print the moulding in the flexible filament TPU.

- Glue the Lexan window into the moulding. I like to use black Shoe Goo.

- Glue the moulding with window into the body opening from the inside of the body using Shoe Goo,.

- Apply masking tape as needed to hold the moulding and window in place over night to allow the glue to dry.